From Britt Hanson, DPhil student at the Wood lab in the Le Gros Clark building, Department of Paediatrics:

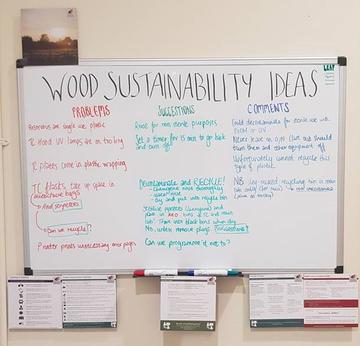

We decided to kick-start implementing Green Impact solutions in our lab and building through the Laboratory Efficiency Assessment Framework towards the end of 2019 as we became aware of the enormous potential for improvement of sustainability within our research environment.

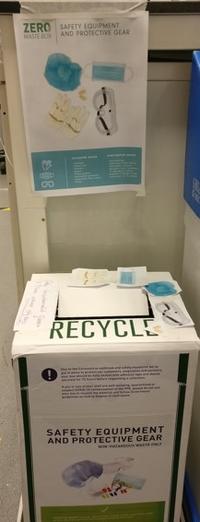

The first major problem we decided to address was the shockingly low proportion of waste that ends up recycled from our building. We recognised that the major hindrance to this was a dearth of recycling bins in the lab, corridors and offices, and critically no bin at the collection point to hand over to the disposal company.

However, the waste collection company were able to provide us with our missing end point bin and we are now confidently able to recycle any non-hazardous dry mixed recycling waste generated in the lab and offices. We introduced an extra bin into each office, as well as the lab. While this has been a recent initiative, we have already observed a major shift in the volume of waste from ‘general’ to ‘recycled’.

The pivotal lesson we have learnt is that we should not assume that common sustainable practice, such as waste separation and disposal, is being implemented in the correct manner. We were able to improve the situation simply, quickly and in a manner that is sustainable going forward without requiring enormous effort for behavioural change. Cleaning staff will also have a simpler and less messy task in dealing with the waste.

Some of the other positive impacts we expect to emerge from this initiative is an improvement in general awareness of sustainability amongst lab members as the conversation has begun and behaviour is beginning to be altered in a simple and natural way.